Virtualization in industrial control with computing and information-based systems implies creating virtual versions of computer hardware platforms, computer network resources, industrial equipment or software control systems.

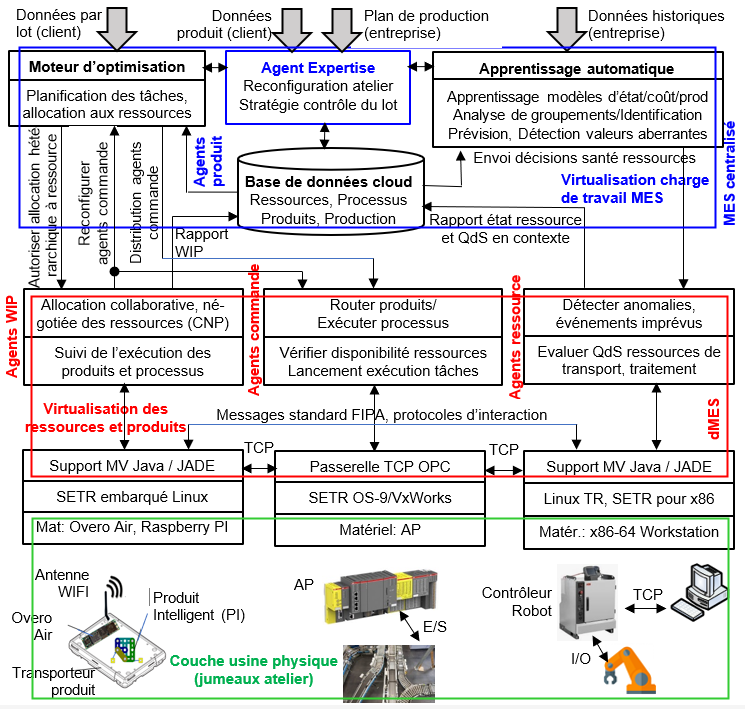

The computer-based industrial control system virtualizes:

- The set of workloads directly connected to the physical entities that are seen as agents representing a resource or product; these are local workloads of the physical layer, e.g., resource monitoring, product routing, dispatching and tracking production order, assigning jobs to resources for product making.

- The set of workloads connected to the computing entities of the information system that are seen as expert or advisor agents acting as optimization engine, machine learning predictor and outlier detector; these are global workloads relative to the full production lifecycle at the complete batch horizon.

Virtualization also represents the main enabling technology for cloud computing applied to the industrial domain. The IT model of Cloud Computing is extended to services which orchestrate operational technology hardware and software elements that transpose, for example, in the Cloud Manufacturing model pools of factory resources (machines, robots) into on-demand making services.