Industry 4.0 promises to raise the levels of productivity and integration of industrial production. Integration concerns systems, whether digital or physical, and distributed at various organizational levels of the production system, but integration must also take into account the human being who will have to face new challenges. Productivity improvement seems to be mainly envisaged by introducing or increasing the number of interconnected autonomous systems as it is the case with Industrial Cyber-Physical Systems (ICPS). However, the design of this type of highly autonomous production system cannot abstain from a “smart” association of human operators at any level of activity, at the risk that they are less and less aware of the state of the processes and the control modes. The human is often considered as the element that must find the solution and make the right decision to control an unexpected situation, but he or she must be given the means to do so.

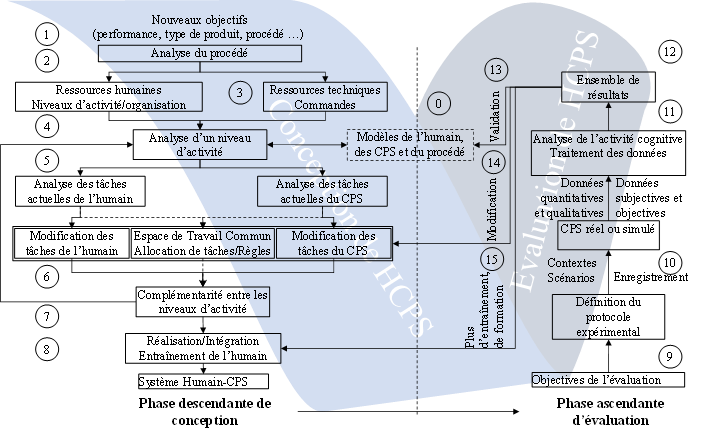

In order to build a cooperation accepted by humans, effective in terms of complementarity between actors, and efficient in avoiding that the cooperation overloads the global activity but, on the contrary, allows an increase in performance, the design of Human Industrial Cyber-Physical Systems (HICPS) must be based on a rigorous methodological approach which takes into account all the above-mentioned capabilities. After a quick presentation of existing design methods, this chapter proposes a detailed description of the different steps required to design HICPS.